The outstanding performance of Vitracore G2 is made possible by a range of significant components that make this product ideal for application in Type A, B, and C buildings where non-combustible materials are required.

Vitracore G2 was the first bonded aluminium panel to be awarded the status ‘deemed non-combustible’ under the Building Code of Australia (BCA) under Clause C1.9e and is fully tested as required to AS1530.1 and AS1530.3

The 0.7mm face skin used with Vitracore G2 is what enables the groove depth to penetrate to the rear of the face skin while still providing the required corner strength and gentle radius on the fold.

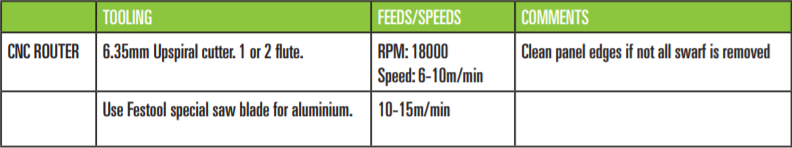

Vitracore G2 can be cut with identical tooling to that used for Vitrabond™ and similar ACP’s.

For the CNC an upspiral cutter is recommended to assist with swarf removal. There is no coolant required on the cutter or groover.

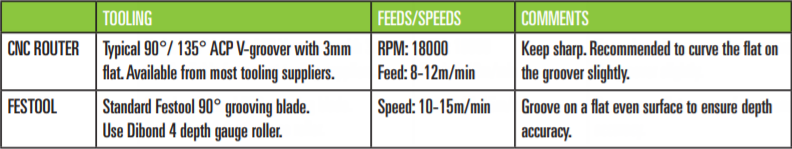

Grooving Vitracore G2 is a simple and easy process, very similar to grooving traditional ACP such as Vitrabond™.

The special profiled core of Vitracore G2 is slightly more exacting on the groove depth but does not present any issues.

For a CNC Router, the perfect depth is just brushing the rear of the aluminium face skin.

The tooling is the same as that for ACP - a 90 degree V-Groover with a 3mm flat. As depicted in the diagram below, for best results the flat should be adjusted to a slight curve. This is simply done with a linisher or bench grinder. Of course, this tool still works just as well for ACP.