The PEANUT® connector is made of a strong reinforced plastic and has rows of teeth around the dowel end to provide high gripping strength when inserted. Self-clamping, single component connector. Creates an incredibly strong joint which is quick and simple to assemble, with the ability to reassemble many times.

The PEANUT 1 connector is designed for manufacturers who have three-axis CNC nesting machines. Once inserted, all panels made with PEANUT components can be packed flat and, depending on the tightness of the joint, can be assembled with no tools. A hole through the length of the component allows for a 3.5mm screw to be used, providing a very strong core and grip strength which secures the component to the panel.

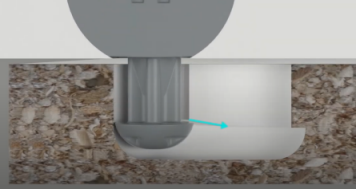

The tool plunges into the board to a specified depth, then descends further whilst moving sideways, then once it reaches its final depth and position it returns (while staying at the full depth) to the original plunge position to lift the tool back out of the board - as shown in  Video 1. EzyNest has the ability to do this, using an Engrave toolpath with 'Follow Contour' engaged.

Video 1. EzyNest has the ability to do this, using an Engrave toolpath with 'Follow Contour' engaged.

_DrillPolyShape Replacement Drillholes for Cutters such as Peanut

When machining is being exported, drill holes in any specified layername can be replaced by polyline sequences. This swapping out is determined by evalutating the variable named _DrillPolyShape[layername] in the current context or any parent context (such as drawing properties). _DrillPolyShape is a builtin system variable name and this substitution is available for any layername you provide (such as _DrillPolyShape[peanut]).

If the _DrillPolyShape variable is present, it should evaluate to a json map. The map can have an optonal member "Layer" containing a replacement layer for the export to replace layername. Plus it should always have the member "shapepoly" which is the xz-poly giving the toolpath needed to replace the drillhole.

The json tags are case independent.

Here is an example map for a typical peanut connector:

Notice that the 3rd xz point[0mm,-14.3mm] in this example is where the peanut cutter is positioned at the original hole centre (x=0mm) and is at a depth of 14.3mm (i.e. z=-14.3mm).

The other 3 points are "ahead" of the true hole position (i.e. negative x) and are at the various depths required to cut the peanut slots as per the manufacturers spec at Intellegent Fixings  and as per the videos. So the cutter starts and finishes 20mm to the left of the reference position in this example.

and as per the videos. So the cutter starts and finishes 20mm to the left of the reference position in this example.

Video 1: Shows how the machining works with peanut connectors to be able to pull two parts together. [0:27 mins]

Video 2: New Connector System seen at the Felder Open Day 2019 [4:03 mins]