In this example a text file ‘ColumnMap.txt’ is used to define the output columns, which are output in the order that the column names appear in this file.

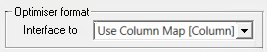

The Optimiser format Interface to needs to be 'Use Column Map [Column], as shown and discussed next.

The file contains a list of the columns required for output.

Example of ColumnMap.txt file

Example of a ColumnMap for Cutrite

This is an explanation of the required columns for output. Further columns can be added but please contact Support for advice.

| Column Name | Description |

| COMP_QTY | Quantity of this component |

| COMP_OPTIMISING | Optimisation code e.g. ‘CSR-Whit-Whit-S’ |

| COMP_MATCAT | The use of the material e.g. ‘Whiteboard’ or ‘Door’ |

| COMP_COLOR | Material colour e.g. ‘White’ |

| COMP_DIMCUT1 | Component dimension 1 – usually Height |

| COMP_DIMCUT2 | Component dimension 2 – usually Width |

| COMP_DIMCUT3 | Component dimension 3 – always Thickness |

| COMP_EDGING | Edging code e.g. ‘1L2S’ |

| COMP_ISGRAINED | Whether or not the material is grained (or patterned 1=Yes and 0=No) |

| COMP_COMMENT | The description of the component e.g. ‘Back’ |

| COMP_CATEGORY | What the component is being used for e.g. ‘Carcass’ |

| CABINET_CODE | The cabinet the component belongs to e.g. ‘F450-1’ |

| MSEQ | The id number of the cabinet |

| JOB_NUMBER | The job number associated with the drawing |

| DOCUMENTTITLE | The CabMaster drawing name |

This example file has been set up to NOT include a header line (i.e. an initial line that contains the column names).

If a header is required, add a comma (“,”) character followed by the required column header name. This should be added to each line.

Example of Header Included

COMP_QTY,Quantity

COMP_OPTIMISING, Material

…..etc

When using the mapped generic formats, comma or tab, a second column of data in the columnmap.txt file is accepted.

This second column provides the column header names for that column, and if present, the output file will be produced with a header line as the first line.

If the second column is not provided, no header line will be produced.Example

Produces output like this...

The output format can be defined by the ColumnMap.txt file, instead of having a predetermined fixed format, for the different output types.

The following are the rules for setting up columnmap.txt.

To designate a different output type, the first line of the columnmap.txt file can optionally be EXT:xxx to indicate that xxx should be used instead of tab or csv as a file extension.

Filenames for some programs, such as Cutrite, spaces in the filename is not allowed. For example, 'test 1' will give an error ('test_1" is a better filename i.e. no spaces).

OptiLink generic formats support pipe separated keys and concatenate. It also supports quoted strings as pseudo keys.

- Pipe separated keys and constants are substituted, removing embedded quotes. If either string is quoted, it will remove all surrounding quotes and re-quote with outer quotes.

Example

- If you quote a string in the pipe separated list it will start by removing the quotes.

Example

- Constant strings concatenate, removing the quotes with these rules…

Example

The predefined variable QUANTITY_EXTD evaluates to the product of cabinet and component quantity.

Edging variables can be used anywhere in the "columnmap" file where it is expecting a variable to substitute. The variables are:

Variable Description Example EDGING_2L2S Edging 2L2S code "1L1S" EDGING_2L2S_DESC 16 char fixed field with EEEEssssJJJJJJJJ (edging+job) “1L1S I5523" EDGING_2L2S_YYYY 2L2S converted to a YYYY code for long, short edges 2L1S converts to "YYY-" EDGING_2L2S_M1 Y or blank for first field of YYYY code EDGING_2L2S_M2 Y or blank for second field of YYYY code EDGING_2L2S_M3 Y or blank for third field of YYYY code EDGING_2L2S_M4 Y or blank for fourth field of YYYY code

Edging information can be entered on the My Setup > Misc Setup page  of the Catalog/Drawing Properties.

of the Catalog/Drawing Properties.

Edging Codes will determine the type of edge labelling that will be used on the reports.

Only populate edge material/thickness when present on that edge checkbox provides the ability to only output edging material on edges that are actually edged. The required output via Optimisation Link will depend on the optimisation software in use. This option allows the thickness of the edge to be output in one field regardless of which edge is edged, or via different fields for each edge. This is in addition to the indicator to specify which edge is edged.

Output only the main face component via Optimisation Link allows only the main face component to be exported via Optimisation Link as some parts have machining on two faces, which causes two components to be exported via opti link.

The following is only pertinent to users with Developer Software.

Edging and Developer

Edging can be specified for any component directly in the Components category.

For example, ‘1L2S’ has been put here to indicate one strip on the Long edge (1L), two on the Short (2S). Any format string can be adopted and formulas can be used as in other places.

When edging information is interfaced through to the "Giben Optisave" format files, the string ‘1L2S’ (or similar) is interpreted and broken into fields...

For more details, see Developer section of this user guide.