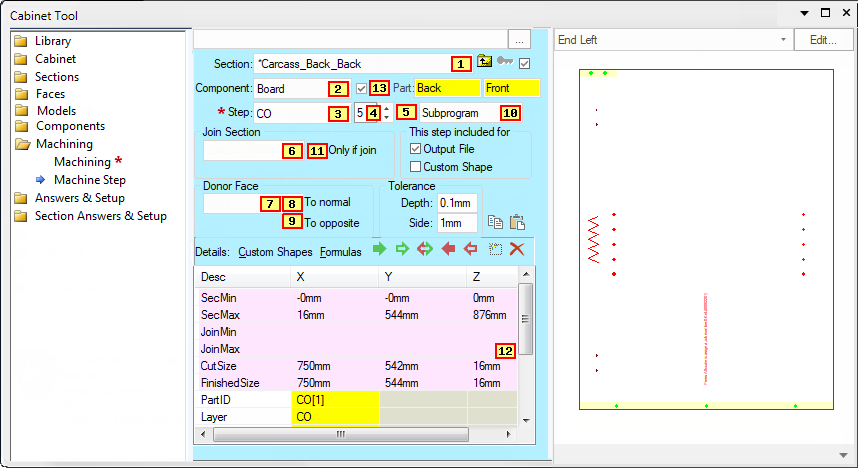

Any controls on this page which can be accessed with a formula are marked with a reference number.

To view the formula name, hold your mouse over the control or click on  to look up the reference in the table below.

to look up the reference in the table below.

To find out what this property page is used for, see the Machine Step page under Cabinet Properties.

| Ref | Variable Name |

|---|---|

| 1 | Section (see Note 1 below) |

| 2 | Component (see Note 2 below) |

| 3 | Step |

| 4 | maxseq (see Note 3 below) |

| 5 | issteppresent |

| 6 | joinhsection |

| 7 | donorface |

| 8 | istonormal (see Note 5 below) |

| 9 | istoopposite (see Note 5 below) |

| 10 | steptype |

| 11 | onlyifjoin |

| 12 | Desc (see Note 4 below) |

| 13 | IsCompPresent |

If you are evaluating formulas inside Section and you use the variable name it will evaluate there to the Section name, giving the same answer as Section in that context. This also applies to...

If you are evaluating formulas inside Component and you use the variable name it will evaluate there to the Component name, giving the same answer as Component in that context.

When a machine step is part of a machine step sequence, this spinner control displays the step number (1,2,3...maxseq).

The spinner is only made available when a defined step is greater than 1 - see Machining Formula Reference notes.

Use # and @ to reference the current step (see Tutorial Machinestep Sequences - Understanding the Name Formula). All formulas in a machine step sequence are the same, it doesn't matter which one is selected when you are editing formulas.

However, when displaying values you will see the value calculated for the currently selected step, and also the preview pane will highlight that step.

For a machinestep, the Desc column can be used as a formula variable and it will evaluate to return the contents of the X Y or Z columns. For example, a formula inside the machinestep grid that says Layer.X will look at the cell in the X column of the row with Desc “Layer” and return the value of that cell.

The Desc cells in this grid are the MachineStepEntry names. A cell in the X Y or Z column can be referenced using contexts which are the Desc names, followed by .X .Y or .Z - For example, a BorderDeco machinestep has various Desc's such as Min, Max, Depth, Layer, RepeatOffset and so on (as shown below). To access the cells in one of those rows using a formula, you can write things like:- Min.X or Max.Y or Layer.X and so on. That is, the formula is written as the Desc followed by .X .Y or .Z to evaluate one of those three cells.

Examples of MachineStepEntry names

For rows that have only one cell (.X) in use, you can drop the .X. For example Layer is the same as Layer.X and either will return the value of the X cell in the Layer row of the grid.

For rows that have exactly two cells (.X and .Y) in use, if you drop the .X or .Y it will evaluate the two cells and return the result as a Point2D. For example, the formula RepeatOffset will evaluate the two cells RepeatOffset.X and RepeatOffset.Y and return them both as a Point2D value.

For rows that use all three cells, if you drop the .X etc, it will evaluate all three cells and return the result as a Point3D value. For example a PolyLine machinestep would have a row with desc Point[5]. Using Point[5] as a formula will therefore evaluate all three cells .X .Y and .Z and return the three results as a Point3D value.

There are also three variables available to a machine step to test whether it has been accepted.

(see Tutorial Machinestep Sequences - Accepting Face)

- isAcceptedFromNormal - this donor step has been accepted by another component on its' normal joining face.

- isAcceptedFromOpposite - this donor step has been accepted by another component to is opposite face to the join.

- isAccepted - isAcceptedFromNormal OR isAcceptedFromOpposite